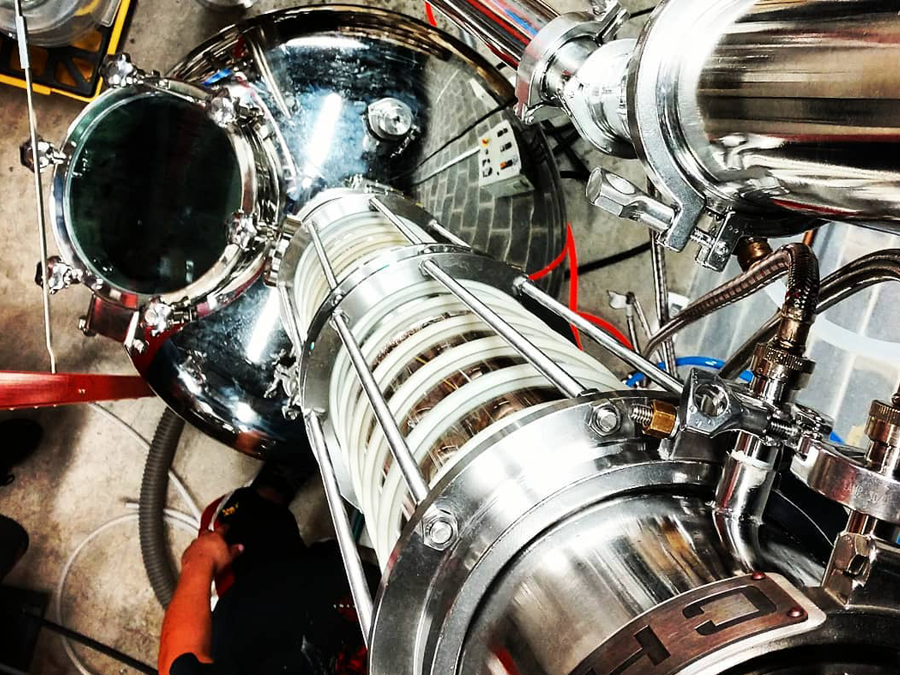

We are a Small Batch grain-to-glass local manufacturer of alcohol spirits. We see ourselves as Hyper - Local. Every single product we produce is hand made within the four walls of our Distilled Spirits Plant (DSP) in Fairfield, NJ. All mashing, fermenting, distilling, aging, blending and bottling is performed locally in Fairfield by our own staff. We do NOT source spirits from any other manufacturers. Raw materials in the form of grains, fruits and produce are aquired from New Jersey farms as well as NY and Pennsylvania. We do utilize some other purveyors since things like Sugar Cane (in the form of molasses) do not grow anywhere around New Jersey. Our goal is to obtain these materials in as high a quality as possible and as close to, or within, New Jersey as possible.

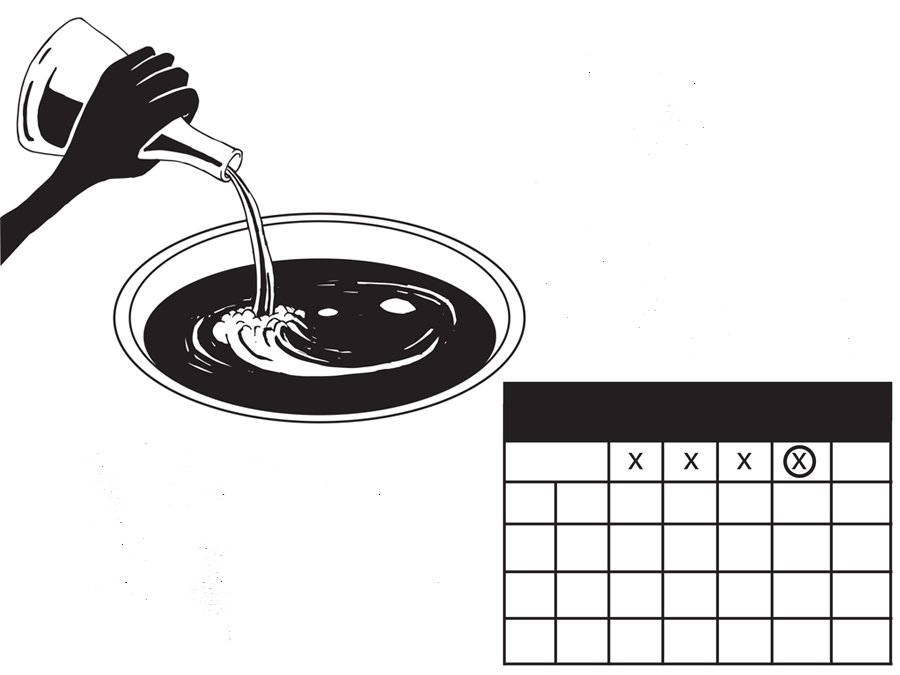

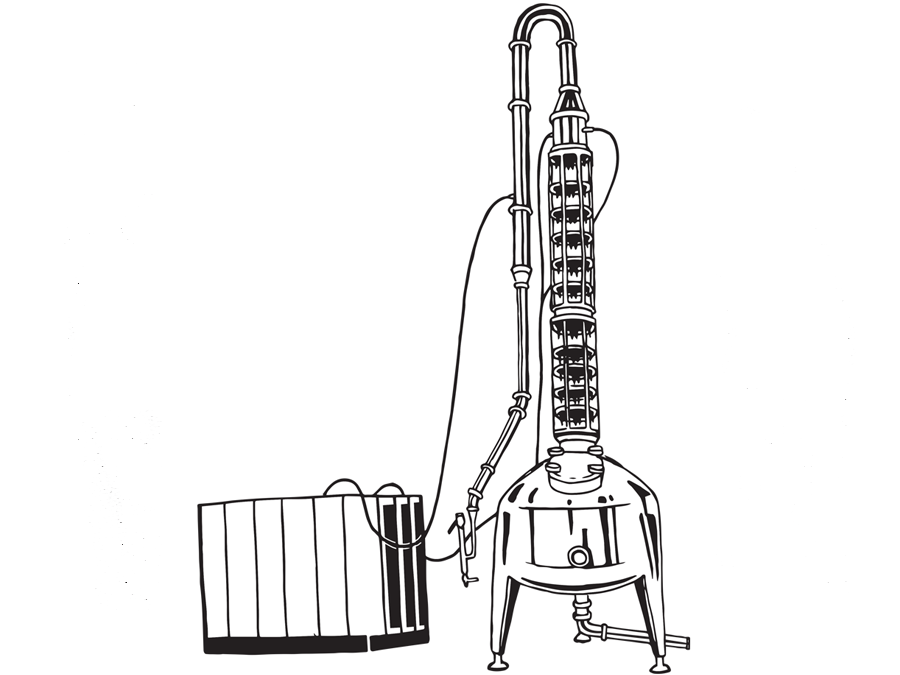

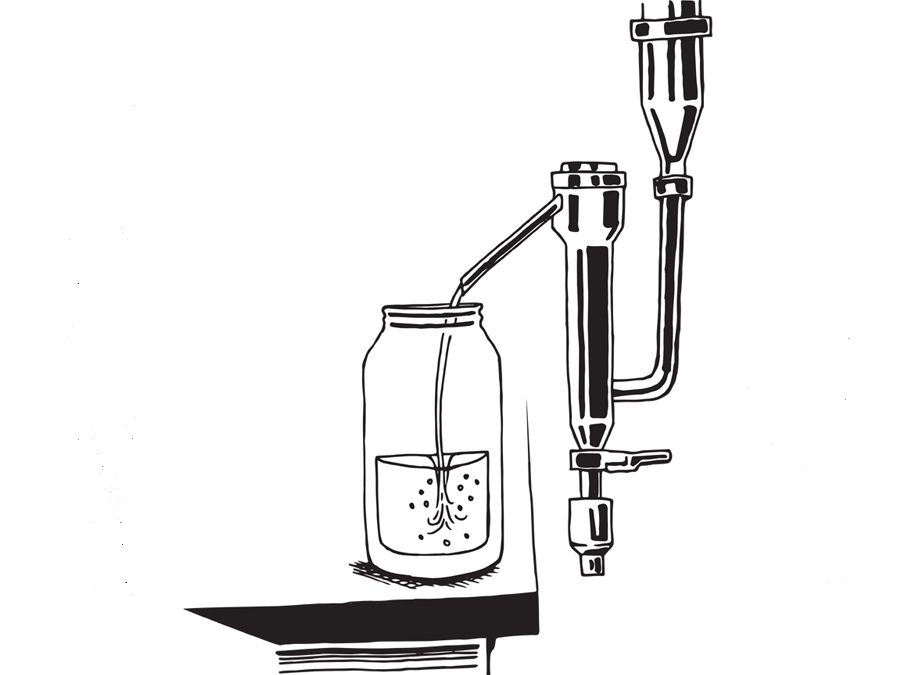

Distillation does not create alcohol. It's purpose is to separate the alcohol from water and other materials and develop flavor. We start the process you can see below by making a beer or wine by utilizing yeast which create alcohol as a byproduct of their consumption of sugar. Being a grain-to-glass facility, we make all of our alcohol on premises and distill all products on premises. This is a significant statement since a good majority of producers source already distilled spirits from industrial manufacturers or other distilleries. We do NOT participate in any of those practices. We craft everything from scratch. Although we may collaborate with breweries, meaderies, wineries or cideries, those products may be fermented at our partner's facility since that would be the point of the collaboration. Those are not our mainstream products and we provide full disclosure on those limited edition spirits which are all distilled on our premises.

Visit our facility and you we not only experience the production first hand but you will get an all encompssing sensory interaction. We are a continual working facility and you will see things in tanks, running in stills, being bottled, etc. We pride ourselves on our production which runs 5-6 days per week. We are an active working DSP that you can witness first hand. All of those products running are the products you are tasting in our Tasting Room.

Check out our process illustrated below and plan a visit soon and maybe even experience a taste right off the stills!